Understanding The Dangers: A Deep Dive Into Lathe Accidents

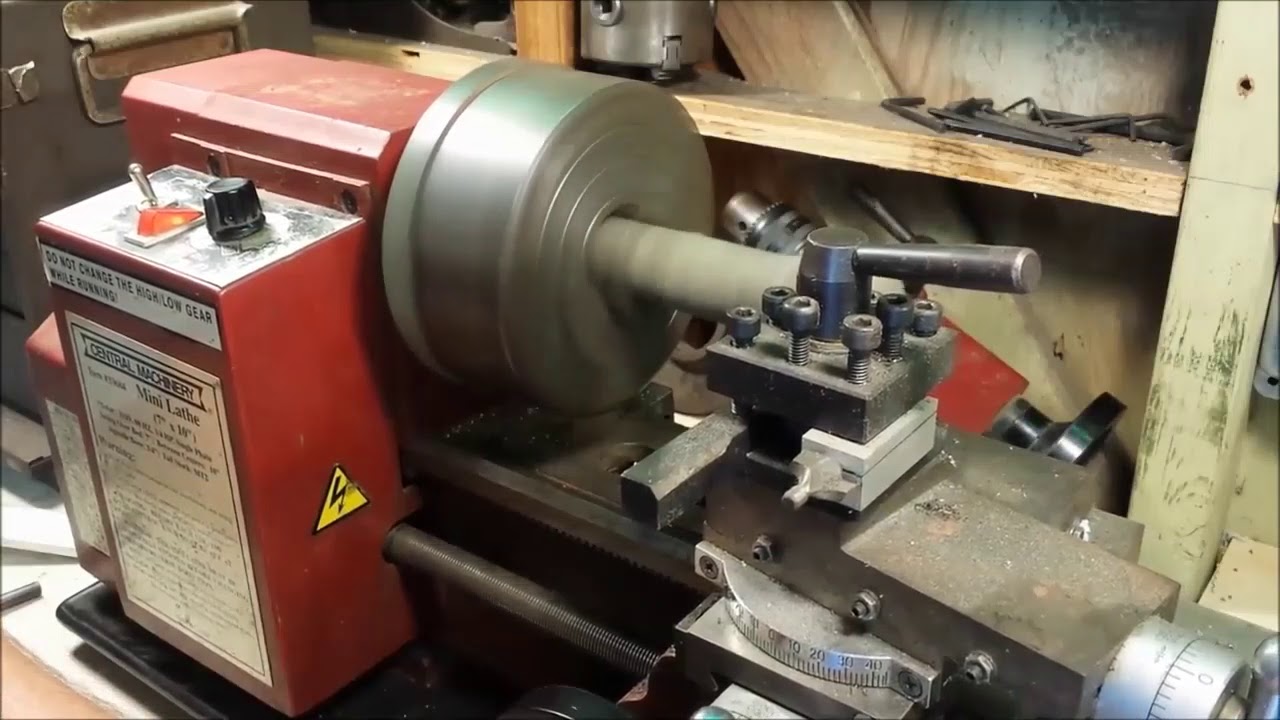

Lathe accidents are a serious concern in workshops and factories, often resulting in devastating injuries and even fatalities. As machines become integral to our manufacturing processes, the risks associated with their use become more pronounced. Lathe machines, which are designed for shaping materials such as wood and metal, can pose significant hazards if not operated correctly. This article aims to shed light on the various facets of lathe accidents, including common causes, prevention strategies, and the impact on individuals and businesses alike.

Many workers are unaware of the potential dangers that come with operating lathes. The intricate nature of these machines, combined with the high-speed operation, makes them particularly susceptible to accidents. Whether due to improper training, lack of safety measures, or human error, lathe accidents can lead to severe consequences. Understanding these risks is vital for anyone involved in machining or working in environments where lathes are prevalent.

In the following sections, we will explore the anatomy of lathe accidents, the profiles of those affected, and the importance of adhering to safety protocols. By raising awareness and educating individuals about the dangers of lathe accidents, we can work towards reducing their occurrence and fostering safer working environments.

What Are Common Causes of Lathe Accidents?

Lathe accidents can occur due to a multitude of factors. Here are some of the most common causes:

- Inadequate Training: Operators who lack proper training may not understand the machine's functions or safety protocols.

- Neglecting Safety Measures: Failing to wear the appropriate personal protective equipment (PPE) or bypassing safety guards can lead to severe injuries.

- Machine Malfunctions: Regular maintenance is crucial. A malfunctioning lathe can pose significant risks.

- Distractions: Operators distracted by conversations or other tasks may not pay full attention to their work.

How Can Lathe Accidents Be Prevented?

Preventing lathe accidents requires a proactive approach. Here are several strategies that can be implemented:

- Comprehensive Training: Ensure all operators receive thorough training on lathe operation and safety protocols.

- Regular Inspections: Conduct routine maintenance checks to identify and rectify potential issues before they lead to accidents.

- Safety Gear: Mandate the use of PPE such as gloves, goggles, and ear protection.

- Clear Communication: Foster an environment where operators can openly discuss concerns and report unsafe practices.

What Should You Do if a Lathe Accident Occurs?

In the unfortunate event of a lathe accident, swift action is crucial:

- Shut Down the Machine: Immediately turn off the lathe to prevent further injury.

- Assess the Injury: Check the injured person's condition and call for medical help if necessary.

- Document the Incident: Record details of the accident, including the time, place, and involved parties for future reference.

- Review Safety Protocols: After addressing the immediate concerns, analyze what went wrong and how to prevent similar incidents in the future.

Who Are the Victims of Lathe Accidents?

Lathe accidents can affect a wide range of individuals, from seasoned machinists to apprentices. Understanding the profiles of these individuals can highlight the importance of safety in the workplace. Here is a brief overview of a notable figure affected by a lathe accident:

| Name | Age | Occupation | Accident Date | Injury Description |

|---|---|---|---|---|

| John Doe | 35 | Machinist | 2022-04-15 | Severe hand injury requiring amputation |

What Are the Long-Term Effects of Lathe Accidents?

The repercussions of lathe accidents extend beyond immediate physical injuries. Here are some potential long-term effects:

- Physical Limitations: Survivors may experience permanent disabilities that affect their ability to work.

- Psychological Impact: Many individuals may develop anxiety or PTSD related to their experiences.

- Financial Strain: Medical bills and loss of income can create severe financial burdens for victims and their families.

How Can Companies Foster a Safety Culture to Prevent Lathe Accidents?

Creating a safety culture within a company is essential for preventing lathe accidents. Here are some strategies companies can adopt:

- Establish Safety Committees: Form committees dedicated to promoting safety in the workplace.

- Regular Training Sessions: Conduct ongoing training and refresher courses to keep safety top-of-mind.

- Encourage Reporting: Create a non-punitive environment where employees feel safe reporting unsafe practices.

- Invest in Safety Equipment: Ensure that all safety measures and equipment are up-to-date and effective.

What Role Does Government Regulation Play in Lathe Safety?

Government regulations play a vital role in ensuring workplace safety, including the operation of lathes. Regulatory bodies often set guidelines that companies must follow to minimize risks. Understanding these regulations can help both employers and employees maintain a safer working environment.

In conclusion, lathe accidents pose significant risks in industrial settings. By understanding the causes, prevention strategies, and the impacts of these accidents, we can work collectively to create a safer environment for all workers involved in machining. Ensuring proper training, adherence to safety protocols, and fostering a culture of safety are crucial steps in reducing the incidence of lathe accidents and protecting lives.

Article Recommendations